Until recently the Australian iron ore industry has been based on the mining of high-grade hematite ore which accounts for approximately 96% of Australia’s iron ore production.

High-grade hematite is often referred to as “Direct Shipping Ore” or “DSO” because it is mined using a relatively simple crushing and screening process before being exported for use in steel mills.

Magnetite ore on the other hand has lower iron content and needs to be upgraded to make it suitable for steelmaking. It is processed to make iron ore pellets which can then be used in steel production. Interestingly, magnetite accounts for approximately 50% of global iron ore production. It’s the magnetic properties of magnetite that means it can be readily refined into an iron ore concentrate.

While magnetite is generally a lower-grade deposit, it is globally accepted as a viable and high-quality feedstock for the production of premium quality, low impurity steel.

To process magnetite the ore needs to be crushed, screened, ground, magnetically separated, filtered and dried. The end result is a high iron grade magnetite concentrate (+65% Fe), with typically very low impurities.

The additional processing cost for the production of magnetite concentrate can be offset by the premium price which it attracts from steel mills because of the high iron content compared to benchmark DSO hematite products.

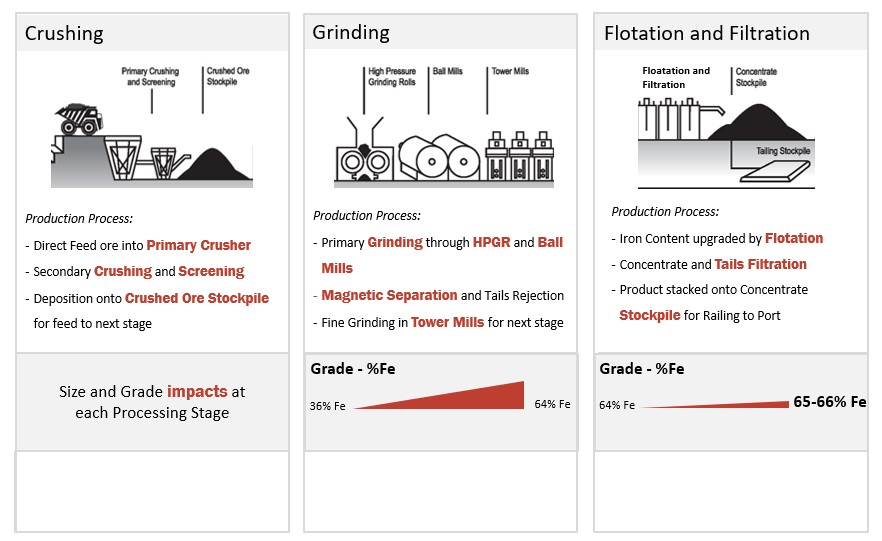

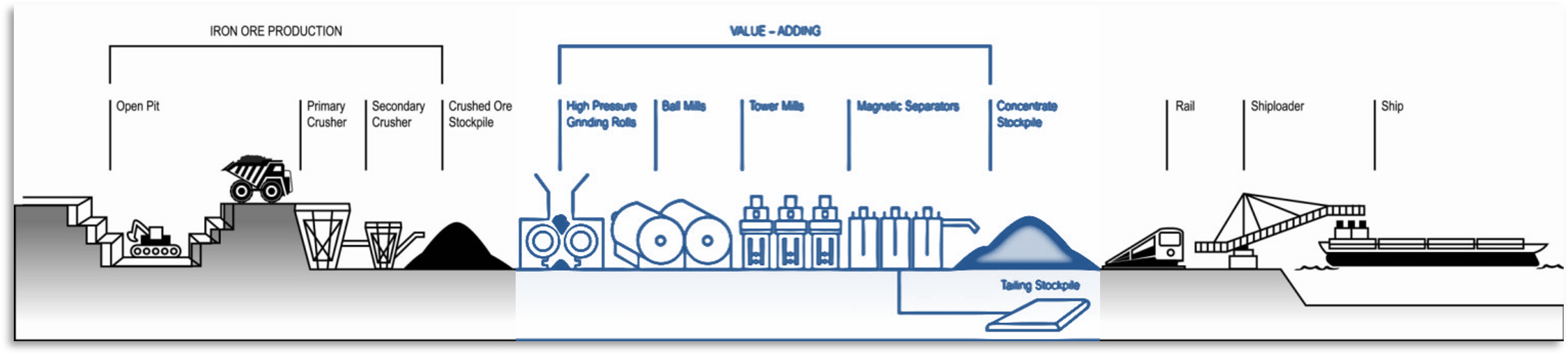

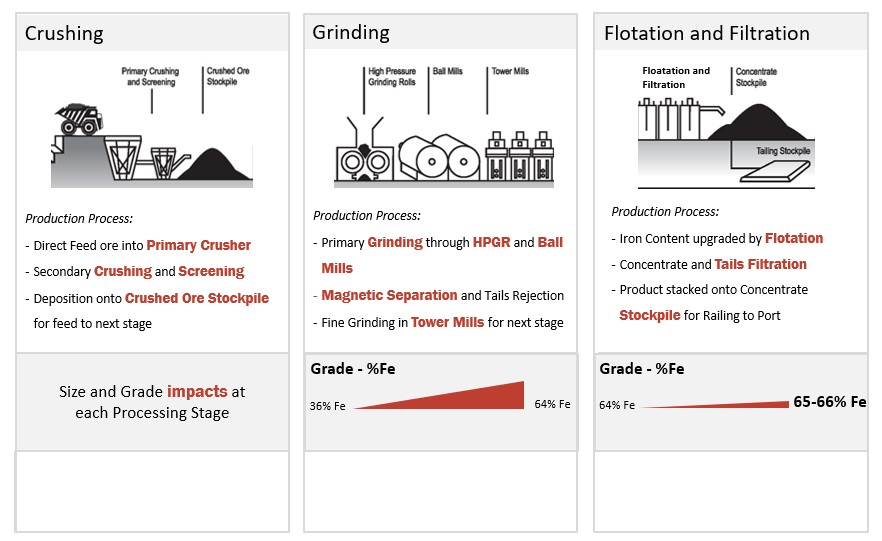

Magnetite ore known as Run-of-Mine (ROM) material is direct dumped by haul trucks from the mine into the primary crusher. Primary and secondary crushers crush the ROM ore to a product size of <60 mm. The crushed ore is then transferred to the Coarse Ore Stockpile (COS), which has a holding capacity of up to 500,000 tonnes of material for downstream processing.

Ore material from the COS is reclaimed by conveyor into a parallel train of two High-Pressure Grinding Rolls (HPGR’s), which grind the ore to a size of 4 mm or smaller. This ore material from the HPGRs is pumped in a slurry to a stage one magnetic separation. A high magnetic field allows separation of non-magnetic material to tailings. Magnetic material remains as a concentrate and is transferred to the primary grinding plant.

The primary grinding plant of four ball mills grinds the ore in slurry into fine particle sizes of <50 µm before further magnetic separation to produce a concentrated magnetite ore stream, with elevated Iron (Fe) grades of ~58%.

Upgrading to final product specification occurs in the flotation circuit. Concentrate is filtered to achieve moisture levels <10% and a final, premium concentrate product with Fe grades of +65%. Product is then transferred by rail to Karara’s Export Terminal at the Port of Geraldton.

Tailings material generated in the ore treatment process is filtered for dry tails stacking where possible, reducing discharge of tailings to Karara’s wet tailings storage facility (TSF), or tailings dam. This enables Karara to reduce water usage and minimise the environmental impact and footprint of tailings material.